Which Is Better for Potassium Humate – Tower Spray Drying or Drum Scraping

If you want potassium humate to be very pure and dissolve well, tower spray drying works best. You should think about important things like how good the product is, how well it dissolves, how fast it works, how much it costs, and if it is right for you before you pick a drying method. These things help you choose which process matches what you want.

Key Takeaways

Pick spray drying if you want pure potassium humate that dissolves fast.

Drum drying costs less and works well for small farms or businesses.

Spray drying makes tiny particles that mix with water easily.

Drum drying makes flakes that need more time to dissolve.

Think about your budget and what you need before you choose a drying method.

Spray drying is best for making lots of high-quality products.

Drum drying uses less energy and is simple to take care of.

Always ask sellers about how pure the product is and how to take care of it before you buy.

Potassium Humate Drying Methods

When you look at potassium humate process, you see two main ways to dry it. These methods are spray-drying and drum-drying. Each method gives you a different type of product. You should know how each process works and where you might use it.

Spray Drying Overview

Spray-drying is a modern way to make potassium humate. You use this method when you want high purity and fast dissolving. Many farmers and companies choose spray-drying for top-quality products.

Process Steps

You start spray-drying by making a liquid solution of potassium humate. You pump this solution into a tall tower. Inside the tower, hot air meets the liquid. The heat turns the liquid into tiny droplets. These droplets dry very quickly. The result is hollow micro-particles. These particles have high solubility and stay very pure. You collect the dry powder at the bottom of the tower. The whole spray-drying process happens fast and keeps the product clean.

Typical Applications

You use spray-drying when you need potassium humate to dissolve quickly in water. This method works well for water-soluble fertilizers. You also see spray-drying used for foliar feeds and biostimulants. If you want a product that mixes easily and gives plants fast nutrition, spray-drying is the best choice. Many large farms and high-tech growers pick spray-drying for these reasons.

Drum Drying Overview

Drum-drying is a classic way to dry potassium humate. You use drum-drying when you want a simple and cost-effective process. This method gives you solid flakes instead of powder.

Process Steps

You start drum-drying by spreading a thick layer of potassium humate liquid onto a hot drum. The drum turns slowly. As the drum heats the liquid, water evaporates. The dried layer sticks to the drum. You use a scraper to remove the dried flakes. These flakes are the final product. Drum-drying is easy to set up and works well for many small operations.

Typical Applications

You use drum-drying when you want a solid form of potassium humate. This method is good for basic soil conditioners and bulk fertilizers. Drum-drying is popular with smaller farms and businesses that want to save money. The flakes from drum-drying may need extra steps to dissolve fully, but they still work well in many fields.

Tip: If you want high solubility and purity, choose spray-drying. If you want a budget-friendly option, drum-drying is a solid choice.

Product Quality

Purity

You want your potassium humate to be as pure as possible. Spray drying helps you get a cleaner product. This method uses hot air to dry the liquid quickly. The process keeps out dust and other unwanted materials. You get micro-particles that have fewer impurities. Drum drying works differently. You spread the liquid on a hot drum and scrape off the flakes. This method can pick up more outside materials. The flakes may not be as pure as the spray-dried powder. If you care about purity, spray drying gives you better results.

Solubility

Solubility means how well potassium humate mixes with water. You need good solubility for fast plant nutrition. Spray drying creates hollow micro-particles. These tiny particles dissolve quickly in water. You can use them in water-soluble fertilizers and foliar feeds. Your plants get nutrients faster. Drum drying makes solid flakes. These flakes take longer to dissolve. You may need to crush or process them more before use. If you want quick mixing and easy use, spray drying is the top choice.

Particle Form

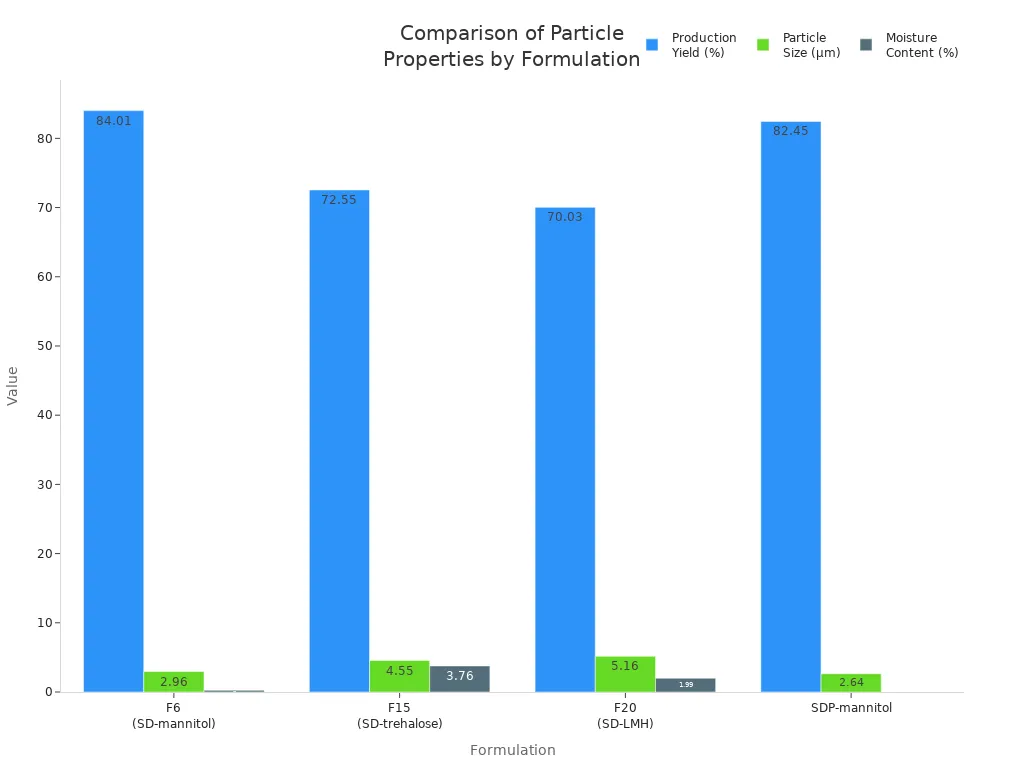

The way potassium humate looks and feels depends on the drying method. Spray drying gives you uniform micro-particles. These particles are small and light. They flow easily and do not clump together. Drum drying gives you larger flakes. The flakes can be uneven in size and shape. You may see more dust or chunks. The table below shows how different drying methods affect particle size, yield, and moisture content.

Formulation | Production Yield (%) | Particle Size (µm) | Moisture Content (%) |

|---|---|---|---|

F6 (SD-mannitol) | 84.01 ± 3.25 | 2.96 ± 1.42 | 0.25 ± 0.03 |

F15 (SD-trehalose) | 72.55 ± 5.42 | 4.55 ± 0.46 | 3.76 ± 0.75 |

F20 (SD-LMH) | 70.03 ± 3.39 | 5.16 ± 1.32 | 1.99 ± 0.77 |

SDP-mannitol | 82.45 | 2.64 | N/A |

You can see that spray drying produces smaller particles with lower moisture. These features help potassium humate dissolve faster and stay fresh longer.

Note: Uniform micro-particles from spray drying make your product easier to use and store. Flakes from drum drying may need extra steps before you use them.

Efficiency & Capacity

Spray-Drying Speed

You want your potassium humate to be ready fast. Spray-drying gives you speed. The process uses a tall tower and hot air. You pump the liquid into the tower. The hot air meets the liquid and turns it into tiny droplets. These droplets dry almost instantly. You collect the powder at the bottom. Spray-drying works quickly because the droplets have a large surface area. You can finish a batch in a short time. Many large farms choose spray-drying for this reason. You save time and get a product that is easy to use.

Tip: If you need to produce a lot of potassium humate in a short time, spray-drying helps you reach your goal.

Drum-Drying Efficiency

Drum-drying uses a different method. You spread the potassium humate liquid on a hot drum. The drum turns slowly. The heat dries the liquid and forms flakes. You scrape the flakes off the drum. Drum-drying works well for thick or sticky materials. You use less energy because the drum keeps heat close to the surface. This method is simple and does not need much space. You can set up drum-drying in small areas. Many small farms and businesses use drum-drying because it is easy to manage.

Drum-drying is good for:

Viscous or sticky materials

Small production spaces

Lower energy use

Scalability

You need to think about how much potassium humate you want to make. Spray-drying is great for large-scale production. You can run many batches in a day. The tower can handle big volumes of liquid. You get a lot of product with each run. Spray-drying fits well in big factories and large farms.

Drum-drying is better for small-scale operations. You can use a compact drum in a small room. You do not need a big tower. Drum-drying lets you start with a small setup and grow slowly. If you want to expand, you can add more drums.

Method | Speed | Energy Use | Space Needed | Best For |

|---|---|---|---|---|

Spray-drying | Very fast | Moderate | Large | Large-scale farms |

Drum-drying | Moderate | Low | Small | Small businesses |

Note: Spray-drying helps you scale up quickly. Drum-drying gives you flexibility in small spaces.

You should choose the method that matches your needs. If you want speed and high capacity, spray-drying is the best choice. If you want efficiency and a simple setup, drum-drying works well.

Cost Factors

Equipment Cost

You need to think about how much money you will spend on equipment. Spray drying uses a tall tower and special pumps. The machines cost a lot at the start. You may need to build a large space for the tower. Drum-drying uses a heated drum and a scraper. The equipment is smaller and easier to set up. You can start drum drying with less money. Many small farms choose drum-drying because the machines fit in small rooms and cost less.

Drying Method | Equipment Size | Initial Cost | Space Needed |

|---|---|---|---|

Spray Drying | Large Tower | High | Big Area |

Drum-Drying | Small Drum | Low | Small Room |

Tip: If you want to save money at the start, drum-drying helps you begin with a smaller budget.

Operating Cost

You must look at how much it costs to run each method every day. Spray drying uses more electricity because you need to heat air and run pumps. You may need more workers to watch the machines. Drum-drying uses less energy. The drum keeps heat close to the surface, so you do not waste power. You can run drum drying with fewer workers. Maintenance for drum-drying is simple. You clean the drum and scraper often. Spray drying needs more care for filters and pumps.

Spray drying: Higher energy use, more workers, more maintenance.

Drum-drying: Lower energy use, fewer workers, easy maintenance.

Note: Drum-drying helps you keep daily costs low, which is good for small businesses.

Cost per Unit

You want to know how much each kilogram of potassium humate costs to make. Spray drying costs more for each unit because the machines and energy use are high. You get a very pure and fast-dissolving product. Drum-drying costs less for each unit. You spend less on energy and workers. The flakes may need extra steps before use, but you save money on each batch.

Drying Method | Cost per Kilogram | Product Form | Best For |

|---|---|---|---|

Spray Drying | Higher | Micro-particles | High-end applications |

Drum-Drying | Lower | Flakes | Small-scale farms |

You should choose drum-drying if you want to keep costs low and run a small operation. Spray drying works best if you need top quality and plan to sell to big farms or special markets.

If you want to grow your business and offer high-end products, spray drying may give you better value over time. Drum-drying helps you start small and save money right away.

Practical Use

Application Suitability

You need to pick the right drying method for your business. If you have a big farm or sell expensive products, spray drying is best. This method makes potassium humate that dissolves fast and stays clean. You can use it in water-soluble fertilizers, foliar feeds, and biostimulants. These products help plants grow better and stronger. Spray drying is also good if your customers want the best quality.

Drum drying is better for small farms or businesses that want to save money. You get potassium humate as flakes. These flakes are good for basic soil conditioners and bulk fertilizers. If you do not need fast dissolving or super clean products, drum drying works well. You can start small and make your business bigger later.

Tip: Think about what you sell and who buys from you before picking a drying method.

Environmental Impact

You should think about how drying affects the environment. Spray drying uses more energy because it heats a lot of air. This means you use more electricity. If you want to help the planet, you can use green energy or better machines.

Drum drying uses less energy. The drum keeps heat close to the product, so you do not waste power. Drum drying also needs less space, which helps lower your impact. Both methods can be clean if you take care of your machines and use good filters.

Spray drying: Uses more energy, needs more space

Drum drying: Uses less energy, needs less space

Note: You can make both methods better for the environment by using clean energy and keeping your machines in good shape.

Maintenance

You want your drying machines to work well every day. Spray drying needs more care. You have to check pumps, filters, and the tower often. If you keep things clean, your product stays pure and your machines last longer. You might need a team to do regular checks.

Drum drying is easier to take care of. You clean the drum and scraper after each batch. The machine has fewer parts, so you spend less time fixing things. If you want something simple, drum drying is easier to use.

Drying Method | Maintenance Level | Ease of Operation | Best For |

|---|---|---|---|

Spray Drying | High | Needs training | Large operations |

Drum Drying | Low | Simple steps | Small businesses |

Remember: Taking care of your machines keeps them safe and your product high quality.

Potassium Humate: Spray Drying vs Drum Drying

Comparison Table

You might want to see how spray drying and drum drying are different. The table below shows both methods for potassium humate. You can look at this table to help you pick the best process for your needs.

Feature | Spray Drying | Drum Drying |

|---|---|---|

Product Form | Hollow micro-particles | Flaky solids |

Purity | Very high | Good |

Solubility | Rapid, easy to dissolve | Slower, may need extra steps |

Production Speed | Fast | Moderate |

Equipment Cost | High | Low |

Operating Cost | Moderate to high | Low |

Scalability | Large-scale, high capacity | Small-scale, flexible |

Maintenance | Needs regular checks | Simple, easy to clean |

Application Suitability | Water-soluble fertilizers, foliar feeds, biostimulants | Soil conditioners, bulk fertilizers |

Environmental Impact | Higher energy use | Lower energy use |

Tip: Check this table to see which drying method matches your business needs.

Pros and Cons

You may want to know what is good and bad about each drying process. Here are the main things to help you decide.

Spray Drying Pros:

You get potassium humate that is very pure.

The product mixes with water very fast.

You can make a lot in a short time.

The micro-particles are easy to pour and store.

You can use it for special or high-quality products.

Spray Drying Cons:

You have to spend more money on machines.

The process uses more power.

You need to check and fix the machines often.

Drum Drying Pros:

You pay less for machines and setup.

The process does not use much energy.

You can start in a small area.

Cleaning and fixing is easy and quick.

You can make small batches if you want.

Drum Drying Cons:

The flakes take more time to mix with water.

You might need extra steps for some uses.

The product is not as pure as spray-dried powder.

Note: Spray drying is best if you want top quality and fast results. Drum drying is better if you want to save money and keep things simple.

Think about what you want for your dry ingredient business. If you want to grow or work with big farms, spray drying gives you more choices. Drum drying is good if you want to start small and spend less.

Choosing the Right Method

Assessing Needs

You want to make the best choice for your potassium humate production. Start by looking at your own needs. Think about your farm size, your budget, and the type of product you want to offer. Ask yourself these questions:

Do you need a product that dissolves quickly in water?

Are you selling to large farms or small local growers?

Is high purity important for your customers?

How much money can you spend on equipment and daily operations?

Do you plan to grow your business in the future?

If you want high solubility and purity, spray drying fits your goals. You get micro-particles that mix fast and stay clean. This method works well for water-soluble fertilizers and advanced plant feeds. Large farms and businesses that want top quality often choose spray drying.

If you want to save money and keep things simple, drum drying may suit you better. You get solid flakes that work well for basic soil conditioners and bulk fertilizers. Drum drying helps small farms and new businesses start with less investment.

Tip: Write down your main goals before you decide. This helps you match the drying method to your needs.

You can use a table to compare your needs with each method:

Your Need | Spray Drying | Drum Drying |

|---|---|---|

Fast dissolving product | ✅ | ❌ |

Low starting cost | ❌ | ✅ |

High purity | ✅ | ❌ |

Small batch production | ❌ | ✅ |

Easy maintenance | ❌ | ✅ |

Supplier Questions

You should talk to suppliers before you buy equipment or product. Good questions help you understand what you are getting. Here are some questions you can ask:

What is the purity level of your potassium humate?

How fast does your product dissolve in water?

Can you show test results or certificates for quality?

What is the cost per kilogram for each drying method?

How much space do I need for the equipment?

What kind of maintenance does the machine need?

How much energy does the process use?

Can I start small and expand later?

What support do you offer after the sale?

Are there any special features that make your product better?

Note: Always ask for samples if possible. Testing the product helps you see if it fits your needs.

You can use these questions to compare different suppliers. This helps you find the best match for your farm or business. You make a smart choice when you know what to expect.

Choosing the right drying method means thinking about your goals, your budget, and your future plans. Ask clear questions and compare answers. You will find the best way to produce potassium humate for your needs.

You should pick tower spray drying if you want very pure potassium humate. This method also helps it dissolve in water quickly. Drum drying is good if you have a small farm or want to spend less money. People in the industry want drying methods that give the same results every time. Sometimes, the amount of water left in the product can change. New spray drying machines, like ones using sound waves or special electricity, make the product better. Before you choose, talk to suppliers and think about what you want to make. Choosing the right drying method helps your farm or business do well.

FAQ

What is the main difference between spray drying and drum drying?

Spray drying makes hollow micro-particles that dissolve fast. Drum drying makes solid flakes that take more time to dissolve. Spray drying gives you a cleaner product. Drum drying is good if you want a simple and cheaper way.

Which drying method is better for water-soluble fertilizers?

Spray drying is best for water-soluble fertilizers. The micro-particles mix with water very quickly. This helps plants get nutrients faster. Spray drying also keeps the product clean and simple to use.

Can I use drum-dried potassium humate for foliar feeds?

You can use drum-dried potassium humate for foliar feeds, but you might need to break up the flakes more. The flakes do not dissolve as fast as spray-dried powder. For the best results, use spray-dried potassium humate for foliar feeds.

Is spray drying more expensive than drum drying?

Spray drying costs more at first. The machines are bigger and use more power. Drum drying costs less for equipment and running it. Pick the method that matches your money and business size.

How do I store potassium humate after drying?

Keep potassium humate in a cool, dry spot. Make sure the container is closed tight so water does not get in. Spray-dried powder stays good longer because it has less water. Always check for lumps before you use it.

Does the drying method affect the environmental impact?

Spray drying uses more power and needs more space. Drum drying uses less power and fits in smaller places. You can help the environment by using clean energy and keeping your machines working well.

How do I choose the right drying method for my business?

Think about what you want your product to do, how much money you have, and what your customers need.

Pick spray drying if you want high purity and fast mixing.

Pick drum drying if you want to spend less and keep things easy.

Ask suppliers for help and try samples if you can.

See Also

Comparing Sodium Humate And Potassium Humate Benefits

Exploring Potassium Humate Fertilizer To Enhance Plant Growth

Key Differences Between Potassium Fulvate And Humate Explained